If your room still feels warm after hours of cooling, the culprit might not be the air conditioner itself—it’s often the installation. Split AC Installation done right can mean fast cooling, quiet operation, and lower energy bills. Done wrong, it can lead to leaks, noise, odors, and painful utility costs. Here’s a clear, step-by-step indoor and outdoor setup process, plus practical checks that work worldwide. Whether you’re supervising a pro or learning how the process should go before hiring, you’ll know exactly what “good” looks like and how to spot mistakes early.

The Real Problem: Why Proper Split AC Installation Matters

For many homes, comfort and efficiency problems trace back to the first day your unit was installed. A misaligned indoor unit, a poorly sloped drain, a kinked refrigerant line, or a rushed vacuum process can quietly erode performance for years. The result? Rooms that never quite reach set temperature, musty smells from standing condensate, whining fans, and higher electricity bills that feel permanent. It isn’t brand-specific—nearly every manufacturer assumes correct installation. When the details are off, even premium systems underperform.

Around the world, heat waves are becoming more frequent, and efficient cooling is a health and productivity issue, not a luxury. The World Health Organization notes rising heat-related risks; reliable, efficient cooling can literally protect lives during extreme heat. Meanwhile, energy prices keep many households on a budget. A well-installed inverter split can deliver up to 20–40% energy savings compared with older fixed-speed units, according to programs like ENERGY STAR, but only if installation matches the engineering.

Here are the most common installation mistakes and their impacts:

- Improper drain slope: leads to indoor water drips, odors, and mold growth.

- Under-evacuated refrigerant circuit: moisture or non-condensables remain, lowering capacity and compressing reliability.

- Wrong line set length or diameter: reduces efficiency and can cause compressor stress.

- Outdoor unit recirculating its own hot air: raises head pressure and power draw.

- Loose electrical connections: intermittent faults and premature component failure.

Out in the field, pulling a deep, stable vacuum and verifying a proper hold can transform performance. A unit that previously struggled at 32°C (90°F) ambient can deliver steady, quiet cooling once the refrigerant circuit is moisture-free and leak-free. Bottom line: correct installation isn’t just “nice to have.” It is the foundation of comfort, safety, energy savings, and equipment life.

Plan, Tools, and Safety: Set Up for Success Indoors & Outdoors

Plan the entire path before mounting anything—from indoor unit placement to the wall penetration, line set route, drain exit, and outdoor clearances. A smooth path reduces bends, speeds the job, and prevents rework. Where possible, pre-check circuit capacity, breaker size, and the wall structure. If you rent or live in a multi-unit building, confirm building policies and noise restrictions.

Safety and compliance first:

- Power: Use a dedicated circuit sized per the nameplate and local codes (e.g., NEC/NFPA 70 in the U.S., IEC standards elsewhere). Consult a licensed electrician if unsure. See NFPA.

- Refrigerant handling: Many countries require certification to open sealed systems. In the U.S., that’s EPA Section 608. Learn more at the U.S. EPA.

- PPE: Safety glasses, gloves, hearing protection, and stable ladders or scaffolding.

- Permits: Local permits or landlord approval may be required.

Tools you’ll want:

- Stud finder, level, tape measure, hammer drill, hole saw (60–70 mm / 2.4–2.8 in), anchors/screws.

- Flaring tool with deburrer, flare nuts, torque wrench (HVAC-rated), tubing cutter, insulation tape.

- Vacuum pump, manifold gauges, micron gauge, nitrogen (for pressure test or purge), leak detector/soapy water.

- Electrical screwdriver set, wire stripper, appropriate cable, disconnect, and surge protection.

Quick-reference guidelines (always confirm with your specific manual):

| Item | Typical Range/Guideline | Why It Matters |

|---|---|---|

| Indoor clearance | 150–300 mm (6–12 in) below ceiling; 100–150 mm (4–6 in) on sides | Ensures smooth airflow and easy service. |

| Outdoor clearance | 300–600 mm (12–24 in) sides/back; 900–1500 mm (36–60 in) top | Prevents hot air recirculation, reduces noise. |

| Drain line slope | 1–2% downward to exit (10–20 mm per meter) | Prevents stagnant water and leaks. |

| Evacuation target | ≤ 500–700 microns; stable hold test | Removes moisture and air for peak performance. |

| Line set length | Common base: 5–7.5 m (16–25 ft); max varies 15–30 m+ | Beyond base length, extra refrigerant may be required. |

| Electrical | Dedicated breaker (e.g., 10–25 A typical for 9k–24k BTU) | Matches unit load; reduces nuisance trips. |

Indoor positioning tips:

- Choose a central wall with a clear throw to the room. Avoid direct sunlight or heat sources.

- Pick a wall that supports the unit’s weight; use proper anchors if not mounting to studs or masonry.

- Plan the shortest, cleanest line route to the outdoor unit with minimal bends.

Pro tip: Measure twice, drill once. Dry-fit the mounting plate, visually route the pipes and drain, and only then commit to the wall penetration. Doing so prevents ugly pipe runs and future service headaches.

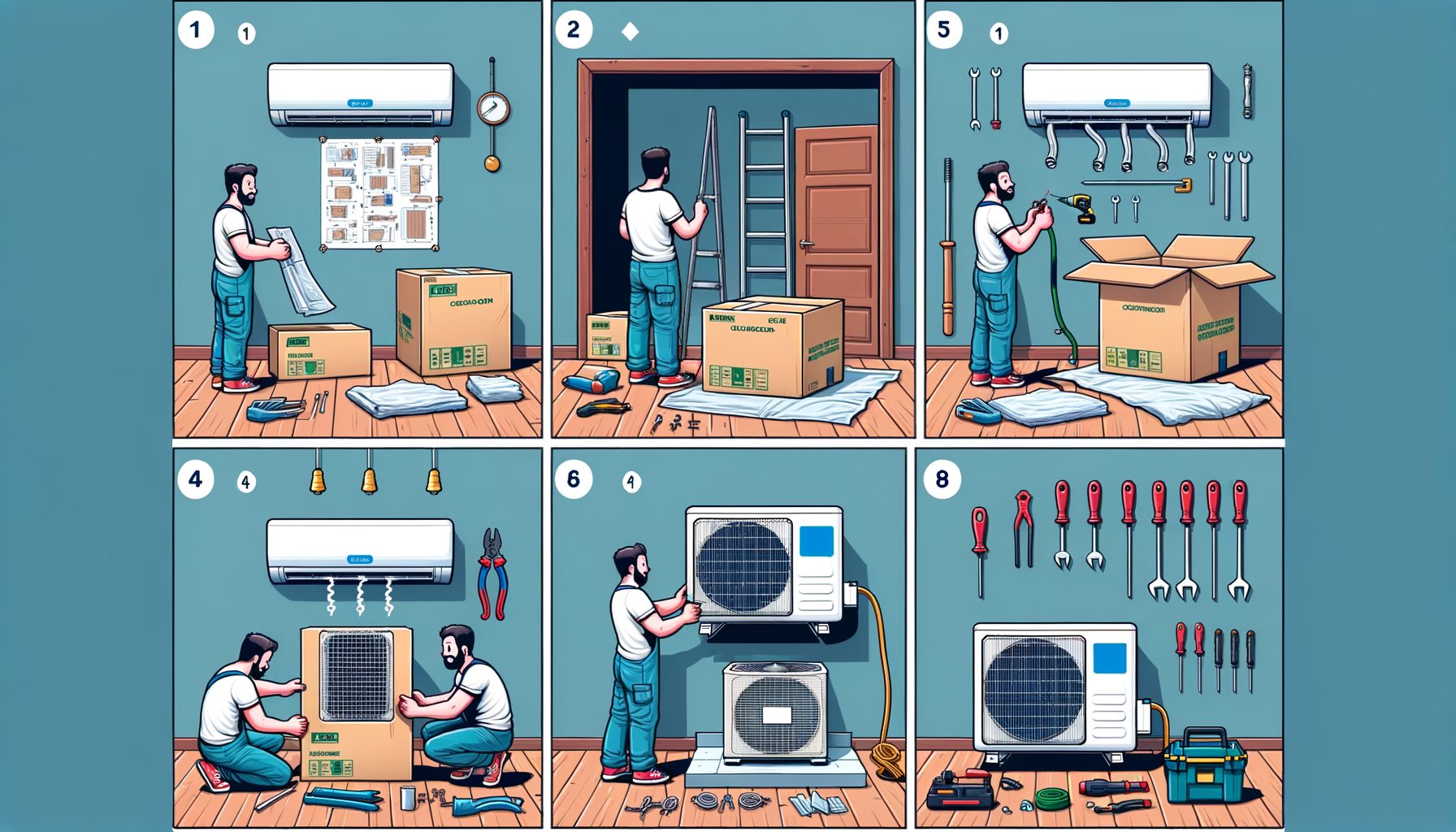

Indoor Unit: Step-by-Step Mounting, Piping, Drain, and Power

1) Mounting plate placement. Hold the plate level on the wall at the recommended height (commonly 2.1–2.3 m / 7–7.5 ft from floor, varying by model). Mark and drill holes. Use suitable anchors and confirm no hidden wiring or plumbing. The plate must be rigid; a sagging plate means a vibrating unit.

2) Plan the wall penetration. Most mini-splits use a 60–70 mm (2.4–2.8 in) hole. Drill with a slight downward pitch (5–10°) outward to aid drainage. Slip a wall sleeve into place to protect the line set and reduce noise. Position the hole so the drain hose maintains continuous fall without dips.

3) Prepare the drain line. Gravity drains need a steady 1–2% slope to the outside or a safe wastewater point. Avoid long horizontal runs without fall. If the exit must go upward, install a condensate pump rated for your unit’s flow. Before hanging the unit, pre-attach the drain hose securely and insulate it in humid climates to prevent sweating.

4) Line set handling. Uncoil the refrigerant lines gently. Cut to length with a tubing cutter; deburr inward edges lightly. Make clean flares with a calibrated tool—no cracks, no over-flaring. Align flares squarely and tighten with a torque wrench per the manual. Insulate both the suction (thicker) and, in hot/humid regions, the liquid line as well. Wrap neatly to prevent condensation and UV damage near the exterior.

5) Electrical connections. With power off, connect the indoor terminal block per your unit’s diagram (often L/N/Signal or numbered terminals). Match wire colors end-to-end between indoor and outdoor. Use ferrules if required, secure strain reliefs, and never mix up polarity on inverter systems—miswiring can cause communication errors or damage.

6) Hang the indoor unit. Hook the top tabs onto the plate, then press the lower body until it clicks. Confirm the unit is truly level side-to-side, and verify the drain hose downhill path. Gently pull the front cover to ensure there’s no undue stress on the pipes or wires.

7) Pre-checks. Pour a cup of water into the drain pan to confirm flow to the exit. Listen for gurgling or slow drainage—fix now, not later. Look through the wall sleeve from outside: kinks, tight bends, or compression points? Correct before sealing. Seal the sleeve edges with weatherproof material to keep bugs and hot air out.

Small-space tip: In narrow apartments, a tidy line-hide (UV-resistant trunking) elevates both looks and serviceability. Keep bends gentle and accessible. If the path is long, add supports every 1–1.5 m (3–5 ft) to protect the flares from vibration fatigue.

Outdoor Unit: Mounting, Line Set Connections, Vacuum, Leak Test, and First Power-Up

1) Location and base. Choose a well-ventilated spot out of direct recirculating hot air—balconies can work if clearances are met. Use a level pad or wall brackets rated for the weight. Add anti-vibration pads to reduce structure-borne noise. Aim for 300–600 mm (12–24 in) side/back clearance and 900–1500 mm (36–60 in) above; keep the coil clean from shrubs or obstacles.

2) Weatherproof routing. Run the insulated line set and control cable neatly. Protect with line-hide or conduit, especially against UV and rain. Support the lines horizontally every 1–1.5 m (3–5 ft). Avoid oil traps (unwanted upward loops) unless specified in the manual for long vertical rises.

3) Connect refrigerant lines. Remove service port caps, keep everything clean, and avoid debris. Align the flares perfectly; hand-tighten first, then torque to spec with an HVAC-rated wrench. Over-torque can crack flares; under-torque can leak. Insulate any exposed fittings to reduce condensation and corrosion risk.

4) Pressure test (recommended). Use dry nitrogen to pressurize the circuit to the manufacturer’s suggested test pressure. Check with a soap solution or electronic leak detector around all flares and joints. A stable reading and no bubbles mean you can proceed.

5) Evacuation. Connect your vacuum pump to the service manifold and a separate micron gauge placed at the far end of the system (not at the pump). Pull down to ≤ 500–700 microns. Close valves and observe the rise. A quick rise suggests a leak; a slow rise that stabilizes might indicate moisture—continue evacuation or perform a nitrogen sweep and repeat. It’s non-negotiable for efficiency and compressor life.

6) Release factory charge. Many splits come pre-charged for a base line length (e.g., 5–7.5 m). With the system in vacuum and verified, use the appropriate hex key to open the liquid and gas service valves fully. If your line length exceeds the base, weigh in additional refrigerant per the manufacturer’s chart (e.g., X g per meter beyond base). Note: Handling refrigerant may be regulated—hire a certified technician where required.

7) Electrical and start-up. Connect the outdoor unit to the dedicated breaker and proper disconnect. Match indoor and outdoor terminal markings exactly. Power on, then start cooling at a moderate setpoint. After a few minutes, check:

- Airflow: strong, smooth, no rattles.

- Condensate: steady drip outside (in cooling mode) after the coil gets cold.

- Temperature split: commonly 8–12°C (14–22°F) between return and supply under normal indoor humidity.

- Line temperatures: suction line cool and sweating lightly; liquid line warm but not hot.

- Outdoor fan: free of obstructions and not recirculating hot exhaust.

- Electrical draw: within nameplate/current expectations.

8) Final sealing and documentation. Seal wall penetrations, secure all caps, and snap the line-hide closed. Log the install date, line length, any added charge, and test readings. Doing so makes future service faster and safer.

Performance tip: In dusty or coastal areas, schedule coil rinses and filter cleaning more frequently. Clean coils and filters can restore 10–30% of lost capacity. For guidance on ventilation and comfort best practices, see ASHRAE. For broader energy efficiency resources, explore ENERGY STAR.

FAQs

Q: Can I DIY a split AC installation?

A: Many steps are mechanical and straightforward, but refrigerant handling and electrical work are regulated in many regions. In the U.S., only EPA 608-certified technicians may handle refrigerants. If you DIY the mounting and routing, consider hiring a licensed pro for evacuation, charging, and final commissioning.

Q: What is the ideal vacuum level?

A: A practical target is ≤ 500–700 microns with a stable hold. If the micron level rises quickly after isolating the pump, recheck for leaks. If it rises slowly and stabilizes high, moisture may still be present—perform a nitrogen sweep and re-evacuate.

Q: How long can the line set be?

A: It depends on the model. Many are rated for 15–30 m (50–100 ft) with specific vertical limits. Past the included charge length (e.g., 5–7.5 m), you usually add refrigerant by weight per meter—follow your manual strictly.

Q: Why is water dripping from my indoor unit?

A: Common causes are a blocked or uphill drain, poor drain insulation causing condensation, or a unit that isn’t level. Confirm slope first. If the drain must rise, install a rated condensate pump and insulate the hose.

Q: How do I choose capacity?

A: Capacity depends on room size, insulation, windows, sun exposure, and climate. Use a reputable load calculator or consult a pro. As a rough start, many small rooms (10–20 m² / 100–215 ft²) need around 9,000 BTU, but gains matter—get a proper calculation for best results.

Conclusion: Bring Comfort, Cut Costs, and Do It Right the First Time

By now, you’ve seen how much Split AC Installation impacts comfort, efficiency, and reliability. The difference between “okay” and “excellent” often comes down to precise basics: a level indoor mount, a clean wall penetration, a truly downhill drain, careful flare joints, correct wiring, an outdoor location with breathing room, and a deep, stable vacuum before opening the valves. These steps are not optional; they are the core of safe, energy-smart cooling.

If you are supervising an install, use this guide as your checklist. Confirm clearances, ask for a micron reading during evacuation, and note any added charge by weight and length. If you are a DIY enthusiast, know your limits: many regions require certification for refrigerant work and licensed electrical connections. Splitting the project—doing the carpentry and routing yourself, then hiring a certified pro for commissioning—can be a smart, legal, and cost-effective middle ground.

The payoff is big. A properly installed inverter split runs quieter, cools faster, uses less electricity, and lasts longer. It is better for your wallet and the planet. And when extreme heat hits—a growing reality highlighted by global health authorities like the WHO—that reliability becomes more than convenience. It is peace of mind.

Your next step: walk through your space and map the install path end-to-end. List your tools, verify electrical capacity, and line up a qualified technician if local rules require it. Bookmark manufacturer resources—many brands publish thorough installation manuals online. For example, check your brand’s technical site or support page (e.g., Daikin, Mitsubishi Electric, LG, Panasonic) for model-specific details. When in doubt, prioritize safety and code compliance, and consult a licensed professional.

Start strong. Plan clearly. Install carefully. Then enjoy that first blast of cool, quiet air knowing you did it right. What is the first improvement you will make—better outdoor clearance, a cleaner drain route, or a proper evacuation with a micron gauge?

Outbound Resources

- ENERGY STAR: Efficient Cooling Guidance

- ASHRAE: HVAC Standards and Best Practices

- Inverter Technology Overview (Energy Efficiency)

- EPEE: Refrigerants and Climate Policy (Global)

- NFPA: Electrical and Safety Codes (U.S.)

- U.S. EPA Section 608: Refrigerant Handling

- WHO: Heat and Health

Sources

- ENERGY STAR. Room AC and Mini-Split Guidance. https://www.energystar.gov/

- ASHRAE. Standards and Guidelines. https://www.ashrae.org/

- U.S. EPA. Section 608 Refrigerant Management. https://www.epa.gov/section608

- WHO. Climate Change and Health: Heat. https://www.who.int/

- NFPA. Electrical Codes and Safety. https://www.nfpa.org/